What is a packaging film roll? Packaging film rolls are widely used in the food, pharmaceutical, and consumer goods industries. They are flexible packaging films, are lightweight and versatile, and have advantages like sustainability and cost-effectiveness. The process of manufacturing packaging film rolls has many stages, each of which is instrumental to final quality and function.

As a flexible packaging manufacturer, we produce packaging film rolls. Now, we will walk you through the manufacturing steps so that everyone understands how packaging film plays a role in maintaining the quality and appearance of the product.

Step 1: Extrusion – the basis of film rolls

Extrusion is the first and most critical step in the manufacturing of packaging film rolls. It involves melting the plastic raw materials and forming them into sheets or films. This process requires that polymers such as polyethylene (PE), polypropylene (PP), or polyester (PET) be fed into an extruder and heated until they are liquid. Then, the molten plastic is extruded through a die to form a continuous film.

During the extrusion process, the thickness, smoothness, and basic characteristics of the film are determined, laying the foundation for subsequent processing. This step is crucial because it directly affects the durability and quality of the final product.

Extrusion

Step 2: Biaxial Stretching – Strengthening Films

After the films are extruded, some will go through a process called biaxial stretching, which is a rather important process. In this process, films are reheated and stretched in both the longitudinal and transverse directions. The purpose of it is to strengthen the mechanical performance, like transparency and flexibility. Biaxial stretching strengthens the film, making it have a higher resistance to tearing and breaking while maintaining the film’s thin and lightweight profile.

This process is critical for scenery that requires strong protective films, such as food packaging or industrial materials.

Biaxial Stretching

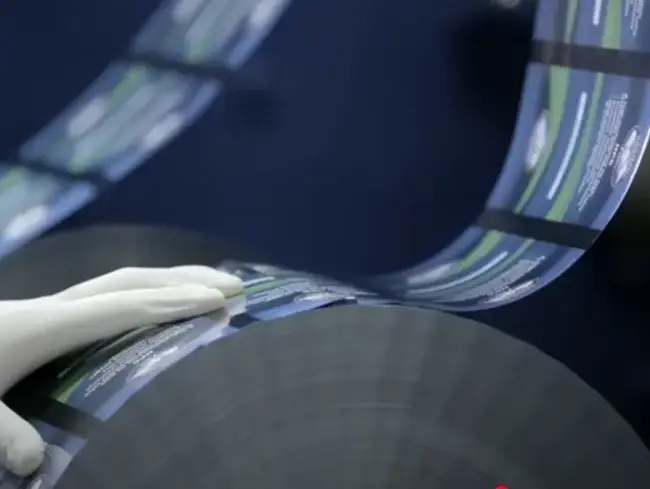

Step 3: Coating and Lamination – Adding Extra Layers

In some cases, films are coated or laminated with additional layers for enhancing their performance. Coating refers to a procedure that applies a layer of material to the film to improve its barrier properties, such as moisture resistance, or to provide a glossy finish. Lamination, on the other hand, bonds multiple layers of different films together, which can add extra strength or improve visual appeal. For example, food packaging film usually adapts lamination with different materials in the case of moisture penetration and extend the shelf life of the product. Both coating and lamination help enhance the performance of films.

Coating and Lamination

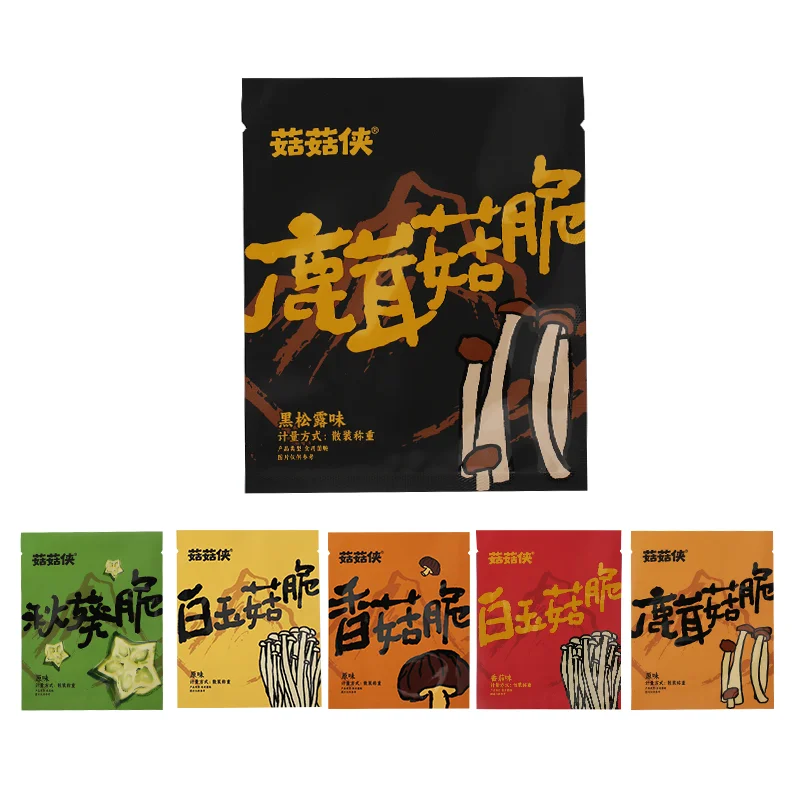

Step 4: Printing – Branding and Customization

Printings on the packaging films are quite significant, especially for to-C products. In this phrase, the film will be printed with logos, information, and decorations to appeal to customers. The versatility of printing techniques like flexographic printing and rotogravure printing enables it to make it attractive. Additionally, digital printing has gained popularity in small-batch manufacturing and customized production. High-quality printing ensures packaging not only protects products but also serves as an eye-catching marketing tool that captures consumers’ attention.

Printing

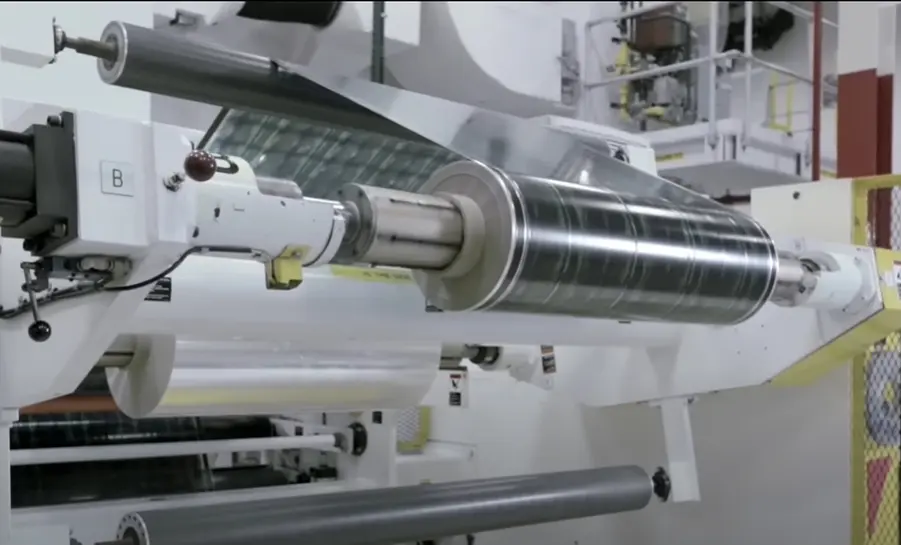

Step 5: Cooling and Setting – Stabilizing the Film

After film printing or orientation, cooling and stabilization treatment are required. In this way can the film can maintain its shape and characteristics. The film is passed through a set of cooling rollers or exposed to cold air to solidify it. Proper cooling is key to achieving the desired thickness, clarity, and flexibility. If the cooling process is not finished correctly, the film may warp, become brittle, or lose integrity, which can affect its functionality in packaging. This step is critical to the consistency and quality of the final product.

Cooling

Step 6: Slitting – Cutting the Film to Size

After the film has cooled and set, the next step is slitting, which cuts the long roll of film into smaller slices that are more easily handled. Depending on different needs, the film can be slit into a variety of sizes, from narrow rolls for snack packaging to wide rolls for industrial use. Slitting uses high-precision blades to cut the film into the exact specifications required. This step ensures that the roll of film can be used for its intended purpose, whether it is food packaging, medical supplies, or consumer products. The final slitting ensures flexible application of the film in different packaging formats.

Slitting

Slitting

Step 7: Quality Control and Testing – Ensuring Consistency

Quality control (QC) is an ongoing process throughout the entire film roll production process. After each stage, the film undergoes rigorous testing to ensure that it meets the required standards. Some key tests include thickness measurement, tensile strength testing, and optical performance evaluation (clarity, gloss, etc.).The film must also pass barrier testing to protect the product from moisture, oxygen, and light adequately.

Conclusion:

After extrusion, orientation, coating, printing, cooling, slitting and quality control, the final roll of packaging film is ready for fulfilling its duty. The manufacturing process is a delicate balance between precision, technology, and creativity. Whether the end product is used to protect food, preserve medicine or enhance the appearance of consumer goods, each step in the manufacturing process ensures that the packaging can effectively perform its role. As consumer expectations continue to rise and sustainability becomes more important, packaging films are also evolving to meet new challenges in the packaging industry through innovations such as biodegradable materials and enhanced barrier properties.

About GQ PACK Flexible Packaging Manufacturer

GQ PACK is a leading flexible packaging manufacturer. We provide custom packaging film roll solutions that meet high standards of barrier performance, printing quality, and seal strength. Our packaging film rolls are available in a variety of structures, such as PET/PE, BOPP/CPP, PET/AL/PE, etc., support 10-color gravure printing, and can be tailored to specific product protection requirements.

At GQ PACK, quality, innovation and flexibility are at the core of everything we do. Whether you are looking for packaging film rolls for automatic filling machines or rolls for bags and pouches, we are your trusted partner.

Contact Us

Don't hesitate to call us[email protected]

Don't hesitate to contact usAnbu Longkeng Xipu Industrial Zone, Chaozhou, Guangdong, China