In the rapidly expanding private label market, retailers and brand owners increasingly rely on professional OEM/ODM packaging suppliers to deliver customized flexible packaging at scale. In this environment, consistent quality and food safety are no longer optional—they are the foundation of long-term brand success.

As a leading food packaging bag manufacturer specializing in contract manufacturing for retailers and brands, GQ PACK understands that quality is built across the entire supply chain. Through a rigorous full-chain quality control system—from raw material traceability to finished product testing—we ensure every batch of packaging meets international standards, helping our clients minimize supply chain risks and build lasting consumer trust.

This article outlines our quality management practices and explains why partnering with a reliable OEM/ODM supplier like GQ PACK provides lasting confidence for your brand.

Raw Material Traceability: The First Line of Defense

Quality begins at the source. To prevent risks before production even starts, GQ PACK implements a strict traceability system for all incoming materials, including polymers (PE, PP, EVOH), inks, adhesives, and additives.

Supplier Evaluation and Certification

We collaborate exclusively with suppliers certified to BRC, ISO, or equivalent international standards. Each supplier is required to provide:

- Declarations of Conformity (DoC)

- Third-party test reports

- Regulatory compliance documentation

Batch Tracking

Every incoming material batch is assigned a unique lot number, with complete records covering:

- Supplier information

- Production date

- Material composition analysis

- Migration test data

This system ensures full traceability back to the original source.

Incoming Inspection

Before materials enter production, they undergo comprehensive inspections, including:

- Visual examination

- Thickness measurement

- Composition verification

- Preliminary migration testing

By intercepting substandard materials early, we effectively mitigate upstream supply chain risks and ensure compliance with FDA, EU 10/2011, and other global food contact regulations.

Production Process Monitoring: Real-Time Consistency Assurance

Flexible packaging production involves multiple complex stages—extrusion, printing, lamination, slitting, and more. To ensure stability and consistency throughout, GQ PACK strictly follows Good Manufacturing Practices (GMP) and the BRC Global Standard.

In-Line Monitoring Systems

Advanced sensors and camera systems continuously monitor:

- Thickness uniformity

- Print registration accuracy

- Lamination strength

- Web tension

Any deviation triggers immediate alerts, enabling rapid corrective action.

Critical Control Points (CCPs)

Based on HACCP principles, we identify high-risk steps—such as ink drying and adhesive curing—and tightly control critical parameters including temperature and humidity.

Environmental and Hygiene Management

Our quality system includes:

- Cleanroom production environments

- Regular equipment sanitation

- Employee hygiene training

These measures prevent cross-contamination and maintain food-grade safety.

Process Recording and Traceability

Every production stage records operating parameters and responsible personnel, creating complete production traceability for every order.

Together, these controls ensure batch-to-batch consistency and eliminate quality variations.

Finished Product Testing: Multi-Dimensional Validation of Safety and Performance

Before shipment, every production batch undergoes comprehensive testing to validate both safety and performance.

Standard Physical Performance Tests

We verify mechanical reliability through:

- Tensile strength testing

- Seal strength testing

- Thickness uniformity checks

- Print adhesion evaluation

Migration and Safety Testing

To ensure full food-contact compliance, we conduct:

- Overall migration testing

- Specific migration testing

- Non-Intentionally Added Substances (NIAS) analysis

All tests are performed in strict accordance with international regulations.

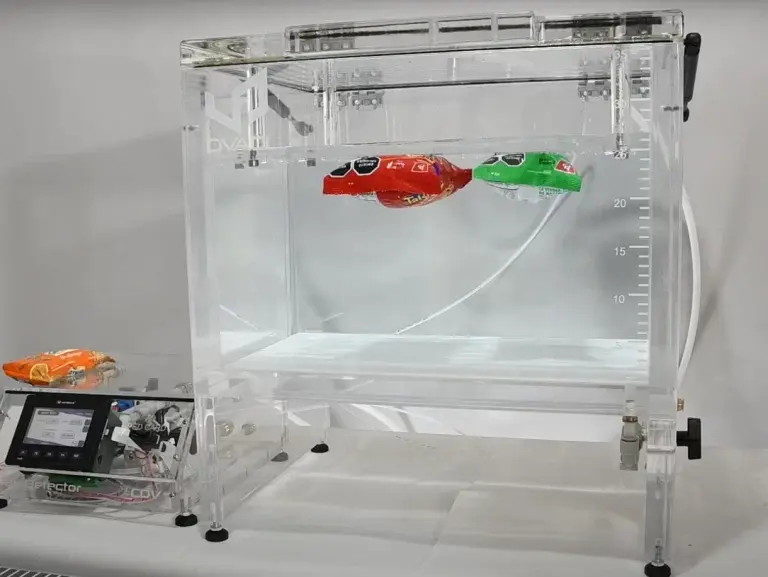

Barrier Performance Testing: Protecting Shelf Life

Barrier performance is a critical focus area for food packaging. We measure:

- Oxygen Transmission Rate (OTR) using ASTM D3985

- Water Vapor Transmission Rate (WVTR) using ASTM F1249

Low OTR prevents oxidation and rancidity, while low WVTR blocks moisture ingress—both essential for extending shelf life.

For applications such as snack and dairy packaging, we consistently achieve:

- OTR < 1 cc/m²/day

- WVTR < 1 g/m²/day

These results help preserve crispness, freshness, and overall product quality.

Each shipment is accompanied by detailed test reports and Declarations of Conformity, simplifying customer audits and regulatory reviews.

GQ PACK’s Quality Commitment: Your Supply Chain Safety Net

Backed by BRC and TÜV international certifications, GQ PACK’s full-chain quality control system has helped numerous retailers and brands achieve zero-recall records.

We go beyond standard OEM/ODM manufacturing by:

- Sharing full traceability documentation

- Providing transparent test reports

- Supporting retail audits and regulatory inspections

This approach delivers:

- Lower supply chain risk

- More stable product quality

- Stronger brand reputation in global markets

Partner with Confidence

Choose GQ PACK for reliable, traceable private label food packaging solutions—from raw materials to finished products.

Contact us today for a free quality consultation:

https://www.topchinapack.com/contact-us/

Together, let’s build a solid foundation for food safety, compliance, and long-term brand success.