في أنظمة تغليف المواد الغذائية، أصبح غشاء التغليف البلاستيكي أكثر أشكال التغليف المرن استخدامًا. فهي تشمل الإنتاج والتوزيع والاستهلاك، وتوفر حماية شاملة لنضارة المنتجات ونقلها وعرضها على الرفوف.

بصفتك شركة رائدة في مجال تصنيع العبوات الغذائية المرنة المخصصة للأغذية، يسعدنا في GQ PACK أن نشارككم ما رأيناه.

أربع نقاط قوة أساسية لأغلفة التغليف البلاستيكية

- أداء الحاجز القابل للضبط - من خلال اختيار طبقات مفردة أو شرائح متعددة الطبقات، يمكن تصميم خصائص الحاجز ضد الأكسجين والرطوبة والضوء بدقة. (مثال: تطيل PA/PE فترة صلاحية اللحوم؛ وتحمي الطبقة الممعدنة مسحوق الحليب المجفف والمكسرات من الضوء).

- القدرة على التكيف الميكانيكية - تعمل الأغشية المرنة والقوية بسلاسة على ماكينات الوسائد والماكينات الرأسية للتعبئة والتغليف والختم بسرعة عالية، مما يعزز كفاءة الإنتاج.

- الامتثال للمعايير الغذائية - عادةً ما تستخدم الطبقات الداخلية البولي إيثيلين البولي إيثيلين أو البولي بروبيلين متعدد الكلور (CPP) من الدرجة الغذائية التي تلبي المعايير الوطنية (GB 4806) ومعايير إدارة الأغذية والعقاقير لسلامة ملامسة الأغذية.

- خفة الوزن وميزة التكلفة - وبالمقارنة مع الزجاج أو المعدن، فإن الأغشية أخف وزنًا وأقل تكلفة للنقل وأقل كفاءة في استخدام المواد، وهي مناسبة تمامًا للإنتاج على نطاق واسع.

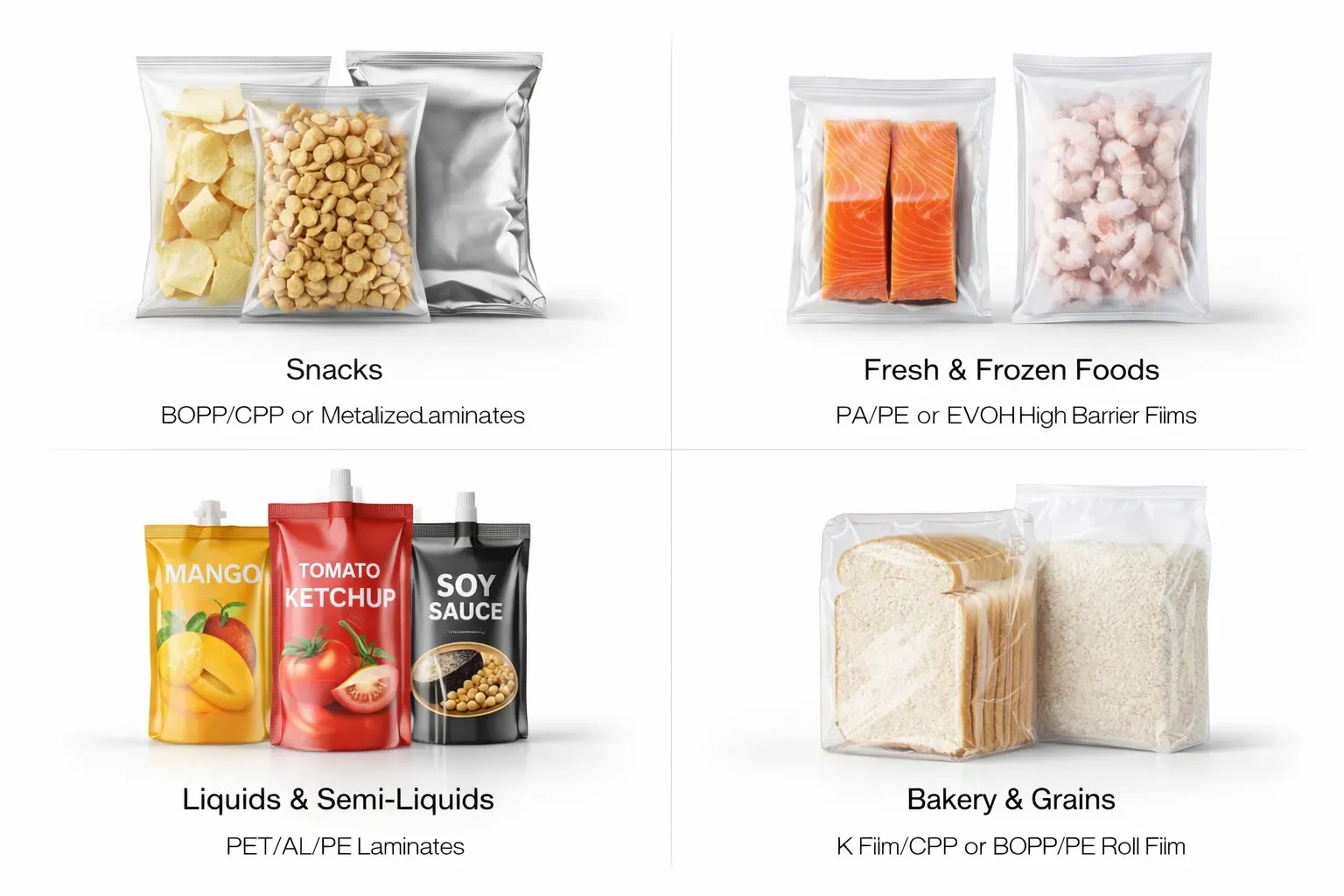

سيناريوهات التطبيق النموذجية

في التقسيم الفرعي لصناعة الأغذية، يستمر التوسع في سيناريوهات تطبيق فيلم اللف البلاستيك.

- الوجبات الخفيفة: صفائح BOPP/CPP أو الصفائح الممعدنة للرقائق والبسكويت والمكسرات - شفافية عالية، ومقاومة للزيوت، وتوافق مع عبوات الوسائد.

- الأطعمة الطازجة والمجمدة: رقائق PA/PE أو EVOH ذات الحاجز العالي للتغليف بالتفريغ؛ مقاومة للثقب وأداء في درجات الحرارة المنخفضة. يمنع بشكل فعال فقدان الرطوبة والرائحة الهيكلية للرائحة.

- السوائل وشبه السوائل: صفائح PET/AL/PE للعصائر والصلصات والتوابل على خطوط ختم القوالب الرأسية.

- المخبوزات والحبوب فيلم K / CPP أو BOPP / PE فيلم لفة K مقاوم للرطوبة وعالي القوة ويمكنه إطالة العمر الافتراضي للخبز والأرز والأطعمة الأخرى من خلال التعبئة والتغليف القابل للنفخ.

تحذيرات عملية

نظرًا لتطور أفلام لفائف الأغذية نحو أخضر, وظيفيةو ذكي الاتجاهات: المواد القابلة للتحلل، والأفلام الوظيفية المتخصصة، والتكامل الذكي للتتبع. يجب أن يتوخى المصنعون في هذه الصناعة الحذر بشأن:

- مطابقة بنية الحاجز مع خصائص الطعام (الحموضة ومحتوى الزيت ومدة الصلاحية المطلوبة).

- استخدم فقط الرقائق المعتمدة الملامسة للأغذية واطلب تقارير اختبار الامتثال.

- قم بتخزين الرقائق بعيدًا عن الضوء والرطوبة؛ قم بتعيين معلمات ختم حراري دقيقة أثناء الاستخدام لضمان سلامة العبوة.

الخاتمة

غشاء التغليف البلاستيكي لا يزال يلعب دورًا حاسمًا في صناعة الأغذية من خلال تحقيق التوازن بين الحماية والكفاءة والامتثال. إن أداء الحاجز القابل للتخصيص، وتوافقه مع خطوط التعبئة الآلية، ومزايا التكلفة الخفيفة الوزن تجعله مناسبًا لمجموعة واسعة من التطبيقات الغذائية. نظرًا لأن الاستدامة والأداء الوظيفي أصبحا من أولويات الصناعة, غشاء التغليف البلاستيكي ستستمر في التطور من خلال مواد أكثر اخضرارًا وهياكل متطورة، مما يدعم سلامة الأغذية وإطالة عمر التخزين والإنتاج القابل للتطوير.

حول حزمة GQ PACK

تعمل GQ PACK كـ شركة رائدة في مجال تصنيع العبوات الغذائية المرنة المخصصة للأغذيةمتخصصون في لفائف أغلفة تغليف المواد الغذائية بالجملة وهندستها حلول لفائف تغليف المواد الغذائية المخصصة. ومع وجود ستة عشر خط إنتاج عالي السرعة، فإن مصنعنا يدعم القدرة المستقرة والتحكم المحكم في التفاوتات وأوقات التسليم الفعالة.

تتبع جميع العمليات متطلبات السلامة والجودة المعترف بها دولياً، مدعومة بشهادات تشمل آيزو 9001, SGS, إدارة الغذاء والدواء الأمريكيةو TUV الألمانية. وبصفتنا شريكاً مباشراً للمصنع، فإننا نقدم مواد موثوقة واتساق عملية يمكن للعلامات التجارية الاعتماد عليها.