Packaging is no longer just a protective film nowadays. It plays a strategic role in brand promotion, logistics, and reducing overall supply chain and transportation costs. Various industries are seeking packaging solutions that balance functionality, cost-effectiveness, and sustainability. Flat bottom bags have become a versatile packaging option that can meet these needs while helping brands optimize supply chain and shipping costs.

In this blog, GQ PACK, a professional flexible packaging manufacturer, will explain to you how these bags optimize the cost for you.

What Are Flat Bottom Pouches?

Flat bottom bag is a flexible packaging with a rectangular box shape at the bottom, which can stand upright on the shelf. This type of packaging bag adopts a sealed edge and four-sided corner brace design, which combines the stability of hard packaging with the lightweight efficiency of flexible materials, thereby optimizing shipping costs and improving warehouse utilization..

Flat bottom bags are commonly used for packaging coffee, tea, pet food, snacks, grains, powders, and high-end goods. They have a professional appearance and can enhance shelf appeal while improving supply chain performance. Unlike traditional self-supporting bags that rely on circular bottom corner braces to maintain stability, flat bottomed bags have a more geometric shape, making them easier to stack and tightly package during transportation.

Key Features of Flat Bottom Pouches That Impact Logistics and Shipping Costs

Compact design

The rectangular base and square edges create a box-like structure, allowing products to be neatly stacked, stored, and displayed. This minimizes space waste on cardboard boxes, pallets, and retail shelves, thereby improving shipping and supply chain efficiency.

Reduced material usage

Compared to hard packaging such as cans, jars, or cardboard boxes, flat bottomed bags require significantly less raw material. This not only reduces costs but also reduces transportation weight and carbon emissions.

Lightweight packaging

The weight of flat bottomed bags is much lower than that of hard containers, which directly reduces shipping costs. This is particularly advantageous for international transportation, where shipping costs are calculated based on weight.

Versatility in sizes and materials

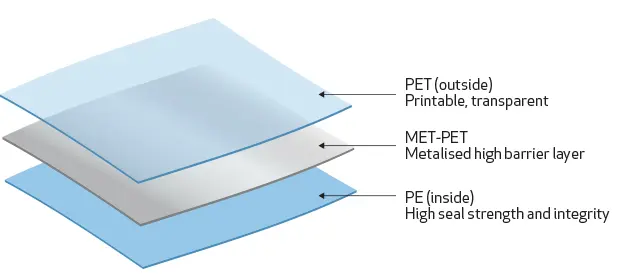

Flat bottom bags come in various sizes and can be used to package a wide range of products, from small snacks to bulk products. Various composite films (such as PET, BOPP, VMPET, and PE) can be used to meet different product barrier requirements.

- PET: High strength, heat-resistant, and chemically resistant, commonly used for outer printing and protection, suitable for high-end packaging.

- BOPP: Lightweight and transparent, with good printability and low cost, commonly used for packaging medium and low-barrier foods.

- VMPET: High barrier, light and oxygen resistant, with a metallic appearance, suitable for products that require long shelf life and high-end feel.

- PE: Soft and safe, with good heat sealing performance, often used as an inner layer to directly contact food and achieve sealing.

Durability and protection

Despite being lightweight, multi-layer films provide strong resistance to punctures, moisture, oxygen, and light, keeping products fresh and safe throughout the supply chain journey.

Supply Chain Optimization Benefits

Efficient palletization

The box-like shape maximizes pallet layouts, allowing more products per shipment. This reduces the number of pallets required, cutting storage and shipping costs.

Warehouse storage savings

Flat bottom bags stack more efficiently than irregular packaging, maximizing the vertical storage capacity of the warehouse.

Simplify delivery

Its shape is compatible with automatic filling, sealing, and labeling systems. This improves the efficiency of the packaging line and reduces manual handling costs.

Reduce shipping costs

The combination of lightweight design and higher capacity utilization has reduced shipping costs and brought significant cost savings to global brands.

Sustainable advantage

Flat bottom bags typically consume less material and energy than hard packaging. Its environmentally friendly design meets consumers’ demand for sustainable development while reducing the impact on the supply chain.

Cost Comparison: Flat Bottom Pouch vs. Other Packaging Types

| Packaging Type | Material Usage | Shipping Efficiency | Storage Space | Branding Area | Cost Efficiency |

|---|---|---|---|---|---|

| Flat Bottom Pouch | Low | High | High | Large | Excellent |

| Stand-Up Pouch | Low | Medium | Medium | Medium | Good |

| Rigid Packaging (Box) | High | Low | Low | High | Poor |

Tips for Choosing Flat Bottom Pouch Suppliers

Choosing the right supplier is crucial for managing the supply chain and shipping costs while achieving strong brand influence. Please consider the following factors:

Barrier performance (MVTR and OTR)

For sensitive items such as coffee, tea, or pet food, please choose packaging bags with high moisture and oxygen resistance levels.

- MVTR(Moisture Vapor Transmission Rate): Refers to the speed at which water vapor passes through packaging materials under certain temperature and humidity conditions. The lower the value, the better the moisture resistance.

- OTR(Oxygen Transmission Rate): Refers to the speed at which oxygen passes through packaging materials under certain temperature and humidity conditions. The lower the value, the stronger the antioxidant protection.

Customized printing and brand promotion capabilities

Collaborate with suppliers who provide high-quality printing methods such as gravure printing and digital printing to create packaging with vibrant colors and rich details.

Sustainable material selection

Choose recyclable, compostable, or biodegradable films to achieve environmental goals and reduce packaging waste.

Global supply and logistics support

Ensure that suppliers can support global distribution, scalable production, and stable delivery times to minimize disruptions.

Conclusion

Flat bottom bags are a convenient packaging solution that can streamline brands’ supply chains, reduce the cost of transport, and help with environmental sustainability. Due to its lightweight, rigid, and durable setup, it is perfect for those companies that aim to maximize logistics and maintain a premium shelf image.

Collaboration with suppliers that provide a good barrier performance, custom solutions, and sustainable materials is crucial to enable the brand to have great operations with a great brand reputation.

About GQ Pack

GQ PACK is a leading flexible packaging manufacturer. We provide custom flat bottom pouch solutions that meet high standards of barrier performance, printing quality, and seal strength. Our packaging film rolls are available in a variety of structures, such as PET/PE, BOPP/CPP, PET/AL/PE, etc., support 10-color gravure printing, and can be tailored to specific product protection requirements.

At GQ PACK, quality, innovation, and flexibility are at the core of everything we do. Whether you are looking for packaging film rolls for automatic filling machines or rolls for bags and pouches, we are your trusted partner.