Packaging is part of the product promise. Brands that depend on third-party converters must treat packaging supply as a strategic risk. The stability of flexible packaging supply ensures consistent product presentation, predictable shelf life, and reliable go-to-market timing—factors that directly influence retailer relationships and consumer trust.

En este blog, PAQUETE GQ, a custom food flexible packaging manufacturer, will share our opinion to help you understand the importance of working with a reliable flexible packaging manufacturer.

What “Stability” Looks like in Practice

Stability means repeatability across multiple dimensions: consistent material composition, reproducible barrier performance, fixed lead times, and predictable unit cost. When buyers say they want a stable flexible packaging supply, they are asking for the same visual, mechanical, and functional result from batch to batch and across sourcing events.

The Direct Impact of Disruptions on Food Brands

When the supply chain falters, the brand carries the ultimate risk. A delay in film delivery doesn’t just stall a factory; it leads to missed retail windows and “out of stock” tags that drive loyal customers toward competitors.

Furthermore, inconsistent packaging leads to shelf-life variability. If a specific batch of pouches has a minor compromise in its oxygen barrier, the product may spoil faster than the date printed on the label. This results in consumer complaints, costly returns, and a “silent” dilution of brand trust that is difficult to quantify but impossible to ignore.

Material Risks: A Brand-Relevant View

Food brands don’t need to be polymer scientists, but they must understand how material fluctuations in a stable flexible packaging supply impact the consumer experience:

Polyethylene (PE): The sealant layer. Variations here lead to seal failures, which are the leading cause of consumer-reported “open packages.”

PET/BOPP: Inconsistencies here affect print quality and the “stiffness” of the bag, making a premium product feel “cheap” on the shelf.

Nylon (NY): Essential for puncture resistance. A downgrade in nylon quality often results in “leakers” during transit.

Aluminum Foil: The gold standard for barriers. Even microscopic defects can lead to oxidation and flavor loss.

EVOH: This high-performance barrier can lose effectiveness under high humidity if the structure isn’t managed correctly.

The Hidden Risk of Material Substitution

One of the greatest threats to a food brand is the “functional equivalent” substitution. Suppliers may swap a specific film grade for another to mitigate their own costs or shortages. While these may look similar, “functionally similar” is not brand-equivalent. One bad batch caused by unapproved structure changes can undermine months of marketing investment and R&D.

This is why a stable flexible packaging supply must be built on “locked” specifications that cannot be altered without rigorous validation.

Change Control vs. Unit Price

In the procurement phase, it is tempting to focus solely on unit price. However, the value of a stable flexible packaging supply lies in the supplier’s change control protocols.

Stable Partners: Have “early warning systems” and multi-source raw material strategies to ensure that even if a global resin shortage occurs, your production line remains unaffected.

Reactive Suppliers: Only tell you there is a problem after the batch has failed or the shipment is late.

Procurement Checklist to Assess Supply Stability

When qualifying suppliers, brands should ask for

(1) lot-specific barrier test data,

(2) documented change-control procedures,

(3) dual sourcing options for critical layers,

(4) pilot run protocols,

(5) historical yield and defect metrics.

These items reveal whether a partner can deliver a stable flexible packaging supply at scale and pace.

Contracts, KPIs and Escalation Mechanics

Translate stability into contract terms: define SLAs for lead time adherence, maximum acceptable defect rate, notification windows for material substitution, and remediation obligations. Require KPIs and periodic QBRs so the supplier’s performance on stable flexible packaging supply is measurable and enforceable.

Practical Mitigation Strategies for Brands

Mitigate risk with strategies such as multi-sourcing, strategic stock of finished reels, joint forecasting, and co-funded trials for alternative laminates. For sensitive SKUs, include roll-to-roll testing and accelerated shelf-life trials so that your stable flexible packaging supply claim is backed by data, not assurance alone.

Conclusión

A predictable, auditable stable flexible packaging supply lets brands scale with confidence. It reduces the time teams spend firefighting packaging issues and frees resources to focus on innovation and market expansion. For brands pursuing sustained growth, packaging stability is not a cost center — it’s a competitive enabler.

Acerca de GQ PACK

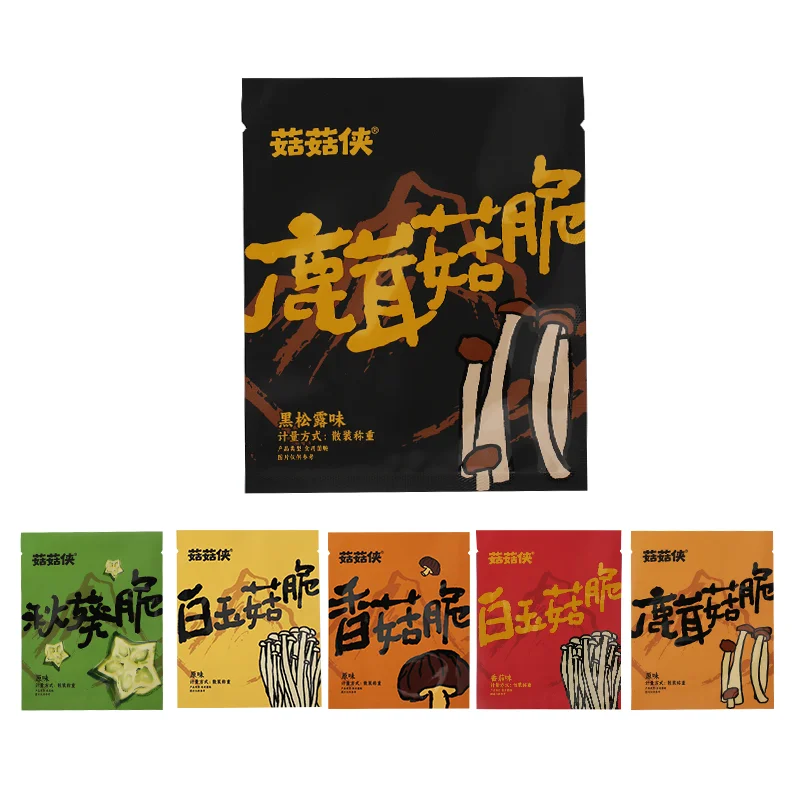

PAQUETE GQ is a professional fabricante de envases flexibles personalizados para alimentos with in-house production focused on batch consistency and supply stability. Our factory operates under locked material specifications, strict change-control procedures, and lot-level barrier testing to ensure repeatable OTR/MVTR performance, seal integrity, and print quality across every order.

Serving global B2B brands, we provide custom flexible food packaging, including pouch structures, barrier films, printing, and functional features such as zippers and windows. By combining scalable manufacturing, traceable QC systems, and predictable lead times, PAQUETE GQ helps brands reduce packaging risk and maintain reliable market supply.