Flexible packaging material powers pouches, bags, rollstock, and sachets across food, pet, personal care, and industrial markets. Lightweight, space-efficient, and highly configurable, these materials deliver barrier protection, mechanical strength, and attractive shelf presence — but choosing the right construction requires understanding layers, functions, and trade-offs.

As a professional flexible packaging manufacturer, GQ PACK will introduce readers to common film series, the role of each layer, typical laminate structures, functional additives, sustainability options, and necessary test items that buyers should pay attention to.

Core Material Families

Polyethylene (PE)

In the field of flexible packaging material, polyethylene is transformed into LDPE (Low-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), and HDPE (High-Density Polyethylene). Their designated duty is for versatile sealant layers and mono-PE structures for recyclability.

Polypropylene (PP)

In the case of polypropylene, generally in the form of BOPP (Biaxially Oriented Polypropylene) or CPP (Cast Polypropylene), it is generally assigned a place as the pack’s outer cover. This is due to the fact that it has a satisfactory combination of good printability and inherent stiffness.

Polyethylene Terephthalate (PET)

It is Polyethylene terephthalate that leads in offering vital physical properties such as better mechanical strength, along with stable temperature resistance. Besides, it gives the final product a special premium finish.

Polyamide (PA) / Nylon

Chemically referred to as Polyamide (PA) or commonly known as Nylon, it is a material that is used specifically when toughness is required in an application. Its most crucial function is to provide good puncture resistance, making it very useful for packaging vacuum and frozen foods.

EVOH (Ethylene-Vinyl Alcohol Copolymer)

As a very specialized polymer, EVOH is added to film constructions for one reason only: to serve as a very strong and targeted oxygen barrier layer. Its function is defined by its very low OTR (Oxygen Transmission Rate).

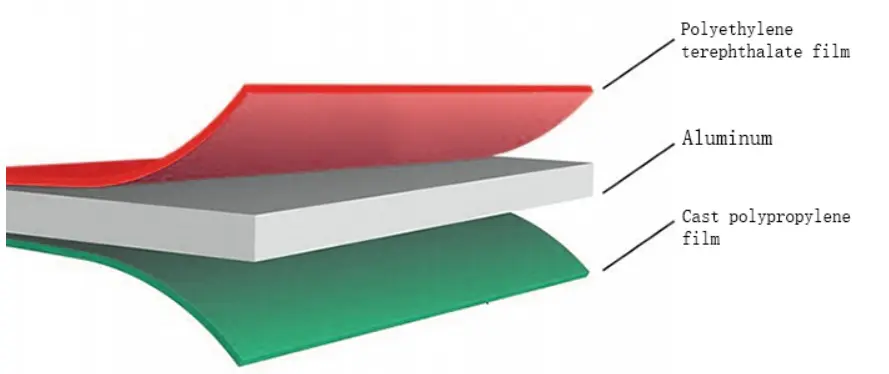

Metallized PET (VMPET) and Aluminum Foil

All three – Metallized PET (VMPET), Vacuum Metallized Polyethylene terephthalate, and standard Aluminum Foil – are applied when absolute protection is required. Their purpose is straightforward: to produce an excellent light and oxygen barrier.

Paper & Bio-polymers

Encouraged by sustainability needs, materials like Paper and Biopolymers like PLA (Polylactic Acid), PBAT (Polybutylene Adipate Terephthalate), and PHA (Polyhydroxyalkanoates) offer distinctive solutions. They are either utilized in order to achieve a natural fiber appearance or to provide fully compostable answers for specific product SKUs.

Layer Roles in a Laminate — Why Multilayers Exist

A flexible laminate is purposeful:

- Outer/print layer: visual appeal and scuff resistance (BOPP, PET).

- Barrier layer: controls moisture, oxygen, and aroma (EVOH, foil, VMPET).

- Strength layer: resists puncture and handling (PA, PET).

- Sealant layer: provides a heat-sealable surface that contacts the product (PE, CPP).

- Tie/adhesive layers: bond incompatible polymers into a stable laminate.

When specifying flexible packaging material, describe the function you need for each layer — not just the polymer names.

Typical Laminate Constructions & Applications

- BOPP / VMPET / CPP — snack chips and low-moisture snacks (good print and moderate barrier).

- PET / AL / PE — frozen or retort foods needing strong thermal stability and a near-complete light/oxygen barrier.

- PA / PE — vacuum packs and frozen seafood where puncture and moisture resistance matter.

- PET / EVOH / PE — coffee, puffed snacks, and oxygen-sensitive items where OTR is critical.

- Mono-PE / PE co-extrusions — recyclable pouch options for chilled and non-sensitive goods.

Ask suppliers for finished-pouch flexible packaging material specs — lab results on the actual laminate, not only raw film data.

Barrier Technology – Choice and Trade-off

- Aluminum foil: almost completely blocks light and oxygen; heavyweight, difficult to recycle.

- Aluminum-coated PET: an economical and efficient barrier material with mechanical properties superior to aluminum foil.

- EVOH: Excellent oxygen barrier performance, but prone to moisture – requires interlayer PE.

- Barrier coating/sol gel: a new method to achieve a higher barrier target for a single material.

When choosing flexible packaging materials, a balance should be struck between MVTR (water vapor transmission rate) and OTR (oxygen transmission rate) requirements, as well as recyclability goals.

Functional Additives, Coatings & Inks

Common add-ons change the performance of these flexible packaging materials without needing a new polymer: anti-fog for chilled produce, heat-seal lacquers, cold-seal coatings, anti-block and slip agents. Inks matter too — water-based, solvent, or UV systems affect recyclability and blocking. Specify any functional coating or ink restrictions up front.

Choosing the right material for your product

Map product sensitivity (moisture, oxygen, light), filling method (hot-fill, retort, MAP), distribution (cold chain vs ambient), and sustainability goals. Use a trade-off matrix: shelf life vs recyclability vs cost. For example, choose PET/AL/PE for long ambient shelf life; select mono-PE with MAP for chilled items you want to recycle.

Examples of use cases

- Snacks: BOPP/VMPET/CPP for crunch retention.

- Coffee: PET/EVOH/PE for OTR control.

- Frozen seafood: PA/PE for puncture resistance.

- Single-serve beverages: spout pouches with PE sealants for recyclability focus.

Conclusion

Selecting the right flexible packaging material is a strategic decision that affects shelf life, consumer experience, and end-of-life outcomes. Learn and understand flexible packaging materials first (barrier, processing, recyclability), insist on finished-package test data, and work with suppliers to pilot laminates under real fill and distribution conditions — that disciplined approach turns material choices into reliable, cost-effective packaging solutions.

About GQ PACK

GQ PACK is a custom flexible packaging manufacturer committed to turning brand concepts into reliable packaging realities. We design and produce custom flexible packaging solutions that balance visual appeal, durability, and functionality.

Equipped with advanced printing lines and precise quality control, our factory delivers consistent performance and on-time production for industries seeking dependable, scalable packaging support. And we have all kinds of flexible packaging materials to satisfy your product needs.