L'emballage alimentaire souple est devenu l'option préférée de nombreuses marques de produits alimentaires parce que les consommateurs recherchent la commodité, les détaillants veulent réduire les coûts et les régulateurs visent à encourager les consommateurs à utiliser les méthodes les moins dommageables pour l'environnement lorsqu'ils consomment des produits dans les rayons.

En tant que fabricant de premier plan d'emballages souples alimentaires sur mesureGQ PACK est prêt à expliquer les raisons de ce changement, à comparer les formats flexibles et rigides, et à vous montrer quand chacun d'entre eux a encore du sens pour les stratégies d'emballage alimentaire.

Qu'est-ce qu'un emballage alimentaire flexible ?

Emballage alimentaire flexible couvre les films, les pochettes et les sacs qui peuvent se plier, se replier ou s'effondrer.

Les matériaux les plus courants sont les suivants

- le polyéthylène (PE),

- le polypropylène (PP),

- le polyéthylène téréphtalate (PET),

- polypropylène à orientation biaxiale (BOPP),

- copolymère d'éthylène-acétate de vinyle (EVOH),

- matériaux composites à base de feuilles d'aluminium.

Les formats typiques sont les sachets à fond plat, les sachets à bec, les sachets à fond plat, les rouleaux, les sachets et les sacs sous vide.

Il s'agit donc d'un produit totalement différent des emballages alimentaires rigides.

Les principaux moteurs de ce changement

Efficacité des matériaux et des coûts

Les formats flexibles utilisent beaucoup moins de matériaux par unité que les conteneurs rigides. Moins de matières premières signifie moins de coûts de matériaux et une réduction de la consommation d'énergie en amont. Cette économie est particulièrement visible à grande échelle, où les emballages à base de film peuvent réduire considérablement les dépenses par unité par rapport aux boîtes de conserve, aux bocaux ou aux bouteilles lourdes.

Avantages en matière de logistique et de stockage

Comme les sachets s'affaissent lorsqu'ils sont vides et se resserrent pendant le transport, l'utilisation des palettes s'améliore et les émissions dues au transport diminuent. Les emballages souples sont plus légers à expédier et moins chers à stocker, ce qui réduit à la fois les frais de transport et l'empreinte carbone de la marque alimentaire.

Amélioration de la protection des produits et réduction des déchets alimentaires

Les emballages alimentaires souples multicouches modernes présentent d'excellentes propriétés de barrière contre l'humidité, l'oxygène et la lumière. Il est possible de combiner des laminés à haute barrière avec l'ajout d'absorbeurs d'oxygène ou d'emballages nettoyés à l'azote, ce qui permet de conserver les produits périssables tels que le café, les snacks et les fruits secs plus frais pendant de longues périodes, réduisant ainsi les déchets et les retours.

Commodité et fonctionnalité pour le consommateur

Les fermetures à glissière refermables, les becs verseurs faciles à utiliser, les paquets à usage unique et d'autres caractéristiques de tolérance à la déchirure améliorent la vie active du consommateur. La conception ergonomique et la légèreté des boîtes offrent aux consommateurs une meilleure expérience, simplifiant ainsi la façon dont ils stockent les produits d'usage quotidien.

L'élan du développement durable

Les emballages souples présentent souvent des émissions de cycle de vie inférieures par unité en raison d'une utilisation de matériaux et d'un poids de transport moindres. Les progrès réalisés dans le domaine des films mono-matériaux, des laminés PE/PP recyclables et des films compostables renforcent les arguments environnementaux en faveur des formats souples par rapport à de nombreuses alternatives rigides.

Comparaison des performances : Emballages souples et emballages rigides

| Paramètres | Emballage alimentaire flexible | Emballage rigide |

|---|---|---|

| Utilisation des matériaux | Faible - films minces, moins de matériau/emballage | Élevée - verre, métal, plastiques épais |

| Efficacité des transports | Excellent - pliable, léger | Plus pauvre - lourd, encombrant |

| Capacité des barrières | Haut (avec stratifiés/EVOH/feuille) | Très élevé pour le métal et les boîtes de conserve ; excellent pour le verre |

| Présence en rayon | Solide (grands panneaux imprimables) | Solide pour un aspect premium (verre/bocaux) |

| Commodité pour le consommateur | Haut - refermer, verser, portion individuelle | Variable - souvent plus lourd, moins portable |

| Coût par unité | Généralement plus faible à l'échelle | Souvent plus élevé (matériel et transport) |

| Recyclabilité | Amélioration (mono-matériaux, collection de films) | Souvent recyclables (verre/métal) |

| Les meilleurs cas d'utilisation | Snacks, café, sauces, poudres, surgelés | Boissons gazeuses, conserves de longue durée, produits fragiles |

Quand les formats flexibles l'emportent

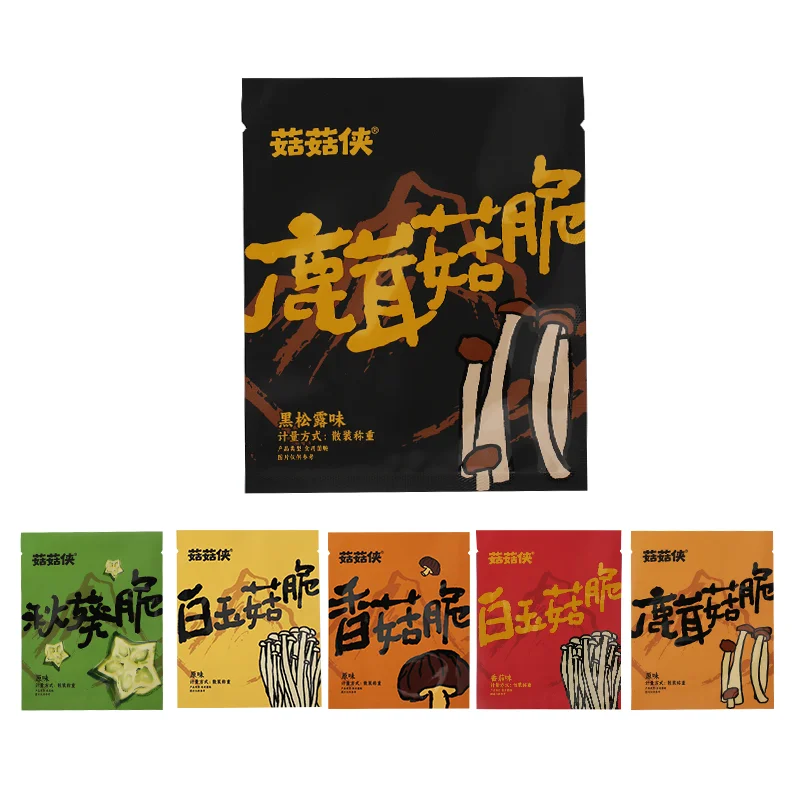

- Snacks et bonbons : Les films légers peuvent conserver une texture croustillante et permettre une impression attrayante.

- Café et thé : Un sac à haute barrière muni d'une valve d'échappement peut efficacement emprisonner l'arôme.

- Sauce et aliments liquides : Une pochette Spout peut remplacer les bouteilles et les boîtes de conserve encombrantes dans de nombreux cas.

- Aliments et compléments en poudre : Pochette à fermeture éclair pour un accès quantitatif facile et une fermeture réutilisable.

- Aliments congelés et réfrigérés : le film souple thermoscellable peut assurer une congélation sûre et un stockage compact.

Quand l'emballage rigide a encore du sens

Les options rigides restent préférables pour des besoins spécifiques : boissons gazeuses (résistance à la pression), stabilité à très long terme des conserves, présentation de qualité (bocaux en verre pour les conserves haut de gamme) et produits nécessitant une protection physique solide. Les contenants rigides sont également plus faciles à recycler dans de nombreux systèmes municipaux, ce qui est important pour les stratégies de développement durable.

Conseils pratiques pour les marques alimentaires

- Commencez par les besoins du produit. Définir la durée de conservation requise, les objectifs de barrière (OTR/MVTR) et les cas d'utilisation par les consommateurs.

- Faire correspondre le format à la fonction. Utilisez des pochettes souples pour la portabilité et la rentabilité ; choisissez des pochettes rigides uniquement lorsque la solidité ou une présentation haut de gamme est essentielle.

- Plan de fin de vie. Donner la priorité aux structures mono-matériaux et communiquer les instructions d'élimination sur l'emballage.

- Tester tôt et souvent. Effectuer des tests accélérés de durée de conservation et de distribution avant de procéder à des changements de format.

- Travailler avec des convertisseurs. Co-développer des structures qui équilibrent la performance des barrières, la qualité d'impression et la recyclabilité.

Conclusion

L'essor de la emballage alimentaire flexible est motivée par une combinaison évidente de facteurs économiques, de performances et de préférences des consommateurs. Les formats flexibles réduisent l'utilisation de matériaux, diminuent les coûts logistiques, améliorent la commodité et, lorsqu'ils sont bien conçus, soutiennent les objectifs de développement durable.

L'emballage rigide a toujours sa place pour des besoins techniques particuliers ou de qualité supérieure, mais pour de nombreux produits alimentaires modernes, les solutions flexibles offrent un mélange supérieur de protection, de coût et d'expérience de l'utilisateur.

Pour les marques alimentaires qui cherchent à innover, le passage au format flexible approprié est l'un des leviers les plus efficaces pour réaliser des gains commerciaux et environnementaux.

À propos de GQ PACK

GQ PACK est un fabricant de premier plan d'emballages souples alimentaires sur mesure est réputée pour sa qualité stable, sa rapidité de livraison et sa forte capacité technique. Nous avons développer sur mesure solutions d'emballage souple pour l'alimentation pour les marques, les détaillants et les distributeurs d'emballages du monde entier.

Nous avons en stock une large gamme de catégories d'emballages alimentaires flexibles, tels que pochettes à bec, pochettes de rangement, pochettes à fond platet sacs d'injection pour boissons. GQ PACK est le fournisseur en qui vous pouvez avoir confiance - réactif, axé sur la qualité et engagé à soutenir le succès de vos produits.