Puffed snacks — chips, corn puffs, rice crackers, and similar products are lightweight, fragile, and highly sensitive to moisture, oxygen, light, and oil migration. The right flexible packaging film preserves crunch, locks in aroma, prevents staling, and presents the product attractively on the shelf.

This guide is from GQ PACK, a custom packaging film roll manufacturer. This article will explain the functional requirements for puffed food packaging, review the common film materials (BOPP, PET, VMPET, CPP), and show how different material combinations form composite films that meet varying shelf-life, cost, and sustainability goals.

Core Functional Requirements

Puffed food packaging film needs to have multiple properties to keep the food inside fresh.

High Barrier

This requirement aims at blocking oxygen and moisture from entering the package. Moisture (water vapor) is the chief enemy of food crispness. MVTR(Moisture Vapor Transmission Rate) represents the rate at which water vapor passes through the packaging film material under certain temperature and humidity conditions, which can reflect the ability of the packaging material to resist moisture penetration. So low MVTR prevents moisture uptake.

Oxygen causes oils to oxidize. OTR(Oxygen Transmission Rate) represents the rate at which oxygen passes through the packaging film material under certain temperature and humidity conditions, reflecting the antioxidant protection ability of the packaging material. So low OTR slows rancidity and off-flavour formation.

Light/UV Blocking

The ultraviolet rays in the light can accelerate the decomposition and deterioration of nutrients in food. Aluminum foil composite film is an excellent shading material that can reflect and block most of the light, protecting food from the influence of light.

Aroma Retention

This means a low-volatility transformation. The film must resist permeation of volatile compounds to preserve seasoning and aroma, at the same time, prevent external odors from entering.

Oil Resistance

Oils can migrate and weaken seals or cause staining. Inner layers must resist grease migration.

Common Flexible Film Materials

BOPP (Biaxially Oriented Polypropylene)

It is a stretched PP film with excellent surface properties for printing and lamination. It has the advantages of high gloss/matte finishes, excellent printability, low cost, good stiffness and tear resistance, and attractive shelf appearance. But its limitation is fatal: Moderate to low moisture and oxygen barrier; not ideal as a single barrier layer for long shelf lives or high-oil products. Often used as an outer decorative layer or in lower-barrier applications.

PET (Polyethylene Terephthalate)PET

This is a high-strength, temperature-resistant engineering film used as an outer or protective layer. People love its excellent dimensional stability, heat resistance, and surface quality for premium printing and varnishes. Provides mechanical protection and scuff resistance. Meanwhile, its MVTR is quite low.PET alone is not a high moisture barrier; it needs a dedicated barrier layer (EVOH, VMPET, foil) for long shelf life.

VMPET / Aluminum Foil

It is a PET or film substrate coated with a thin metallic layer (vacuum metallization) or full aluminum foil. Its strengths include strong light/UV shielding, improved oxygen and aroma barrier (foil > metallized), and premium metallic appearance. On the other hand, a metallized layer can crack under stress — risking barrier failure; metallic layers complicate recycling and are non-monolithic. Aluminum foil gives the best barrier, but increases cost and weight.

CPP (Cast Polypropylene)

This is a soft, heat-sealable polypropylene film often used as the inner sealant layer. It has Excellent heat-sealability, suitable for hot-fill and high-speed sealing operations; good flexibility and impact resistance. Compatible with oily products when formulated correctly. While its limitation is moderate barrier performance, usually paired with barrier layers to achieve the desired shelf life.

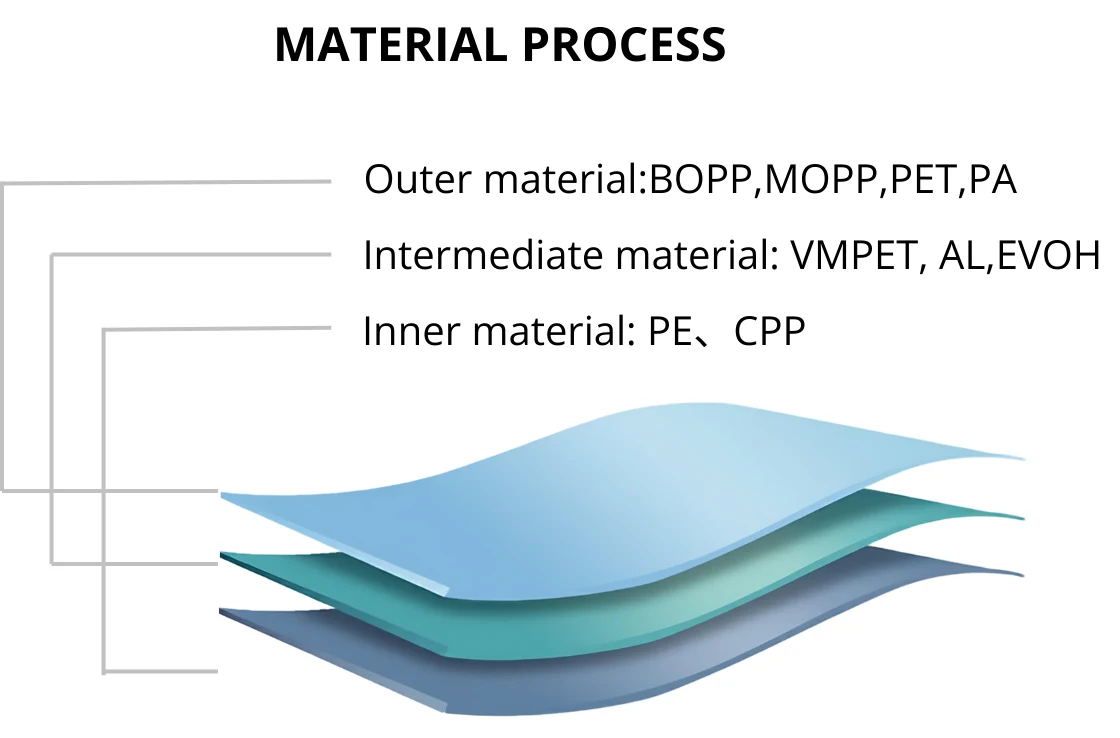

How Materials are Combined into Composite Films

Single films rarely deliver every required property. Multilayer laminates combine the best features:

- Outer decorative layer (BOPP or PET) for print and scuff resistance.

- Barrier layer (VMPET, aluminum foil, EVOH) to stop light/oxygen/moisture.

- Mechanical/strength layer (PET, PA/nylon) for puncture resistance.

- Sealant layer (CPP or PE) in direct contact with product to enable robust heat sealing and spout/cap compatibility.

Different assemblies tune the package performance, shelf life, and recyclability:

- Higher barrier builds (e.g., PET / VMPET / CPP) maximize light and moisture protection — ideal for long shelf life and high-oil snacks.

- Oxygen-focused builds (e.g., PET / EVOH / PE) prioritize OTR control while keeping the package lighter.

- Mechanically reinforced builds (e.g., PET / PA / CPP) add puncture resistance for mixed-ingredient snacks with hard particulates.

- Mono-polymer or PE/PE coextrusions favor recyclability but may need more creative barrier strategies (e.g., thicker PE or barrier coatings).

Testing Metrics Every Buyer Should Require

When evaluating suppliers and film options, request objective data for the specific laminate and the finished pouch:

- MVTR (Moisture Vapor Transmission Rate) — lower is better for crispness

- OTR (Oxygen Transmission Rate) — key for oxidation-sensitive oil content

- Grease resistance / Oil migration tests — ensure oil won’t degrade seals or appearance.

- Puncture & tensile strength — to validate mechanical durability in handling.

- Light/Opacity measurement — or provide metallization/foil thickness for light protection.

Specific numeric targets depend on the product formulation and desired shelf life.

Design and Cost Trade-offs

Barrier vs cost: High-barrier films (foil, EVOH) cost more but reduce product loss. The right choice depends on target shelf life, product oil content, and retail distribution.

Appearance vs recyclability: Metallic or multi-material laminates look premium but complicate recycling. Mono-PE or PE-based coextrusions are easier to recycle but may need thicker films or protective measures.

Seal reliability vs thinness: Thinner films save material and shipping cost but can sacrifice seal strength and puncture resistance.

A lifecycle view — comparing product waste from inadequate packaging versus material footprint — helps make rational tradeoffs.

Typical Layer Combinations

Below are commonly used multilayer assemblies. Each row lists the stack (outside → inside), primary function, suitable puffed snack use, advantages, and limitations.

| Layer combination (outside → inside) | Primary function | Suitable for | Advantages | Disadvantages |

|---|---|---|---|---|

| BOPP / VMPET / CPP | Decorative outer + metallized barrier + sealant | Short–medium shelf puffed snacks, snacks for retail | Cost-effective, glossy look, good light blocking, reliable seal | Moderate oxygen barrier only; metallized layer can crack under stress |

| PET / VMPET / CPP | Premium print + metallized barrier + sealant | EVOH still complicates recycling; it requires proper local streams | Strong printability & scuff resistance, good light/partial barrier | Multi-material; recycling complexity, higher cost |

| PET / EVOH / PE (or CPP) | Print layer + oxygen barrier + sealant | Products needing strong oxygen protection (longer shelf) | Excellent OTR control, lighter than foil | Mid–long shelf, oil-containing chips, and premium snacks |

| PET / PA (nylon) / PE (or CPP) | Print + puncture resistance + seal | Snacks with hard particulates or large fillings | High puncture resistance and toughness | Moderate barrier; more complex lamination |

| BOPP / Metallized BOPP / PE | Decorative + metallized + seal | Short-life, low-cost snack packs | Low cost, good print quality | Limited barrier for long shelf or high-oil products |

| PE / EVOH / PE (coextruded or laminated) | Mono-polymer style with EVOH core | EVOH is sensitive to moisture, complicating recycling | Good OTR control while enabling PE outer/inner for easier recycling | EVOH is sensitive to moisture; complicating recycling |

| PET / Aluminum foil / CPP | Print + foil barrier + seal | Highest barrier long shelf life, gift/retail packs | Superior light/oxygen/aroma barrier | Highest cost; foil materially limits recyclability |

| PE / PE (coextruded mono) | Recyclability focused mono-PE | Short shelf, refill packs, price-sensitive lines | Easier to recycle where systems exist; lower complexity | Lower barrier; may require nitrogen flushing and thicker gauges |

Conclusion

Choosing the right flexible packaging film for puffed snacks is about much more than appearance — it directly determines freshness, shelf stability, and brand reputation. Puffed products are especially vulnerable to moisture, oxygen, light, and oil migration, which means packaging must balance multiple functions: crispness preservation, aroma retention, oxidation control, and grease resistance. No single material delivers all these properties, so composite films are engineered to combine decorative appeal, barrier protection, strength, and sealing reliability.

About DQ Pack

GQ PACK is a trusted flexible packaging manufacturer offering a wide range of custom packaging films for puffed food. Whether you require a clear laminate film to showcase your beverage or an aluminum laminate film for long-term storage, GQ PACK can design and produce films tailored to your beverage type, shelf life requirements, and branding needs.

Contact Us

Don't hesitate to call us[email protected]

Don't hesitate to contact usAnbu Longkeng Xipu Industrial Zone, Chaozhou, Guangdong, China