Have you ever wondered if a spout type will cause consumer dissatisfaction? Many are complaining about the problem with the spout of certain products online. Therefore, selecting the correct spout type is a small decision with big consequences. The wrong spout can cause leakage, clogging, production slowdowns, poor consumer experience, or even regulatory headaches.

This guide walks packaging managers, product developers, and procurement teams through the factors that matter — position (side vs. top), diameter, material, filling compatibility, and common pitfalls — so you can specify the right スパウトパウチ structure for your product and line.

Why Spout Type Matters

A スパウトパウチ is more than a pouch + cap. The spout type determines:

- How the product dispenses (flow control, splatter, dosing)

- The speed and reliability of automatic filling and sealing

- Consumer ergonomics (single-hand squeeze, pour, or sip)

- Leak risk during transport and shelf life

- Cleanability and clogging behavior for viscous or particulate products

Get the spout type right, and you minimize complaints, reduce downtime, and protect brand reputation.

Spout Position: Side Spout vs Top Spout

Side spout (corner / side-fold)

- デザイン: Mounted near a bottom corner or side seam; often used with corner reinforcement.

- 最適: Purees, baby food, pastes, honey, thick sauces, nutrition gels.

- メリット: Excellent for controlled squeezing and single-handed feeding; reduces drips when dispensing small amounts. Child-friendly ergonomics make it ideal for on-the-go and baby food use.

- Tradeoffs: Requires more precise pouch forming and spout welding; may need reinforced panels to avoid stress at the corner.

Top spout (center / top cap)

- デザイン: Positioned on the pouch top-center or near the top seam.

- 最適: Juice, RTD beverages, protein drinks, thin sauces, liquid seasonings.

- メリット: Easier to fill at high speeds; generally simpler to automate on standard spout-filling lines; fast pouring for low-viscosity fluids.

- Tradeoffs: Less control for precise, small-volume dispensing; may be less ergonomic for single-handed squeezing of thick products.

Choosing the Right Diameter for Flow Control

Spout diameter hugely affects usability and clogging risk. Typical ranges and use cases:

- Small (6–9 mm) — Thin liquids (water, sports drinks, clear juices); good for controlled pours and anti-spill.

- Medium (10–16 mm) — Most beverage concentrates, yogurt drinks, many purees, and medium-viscosity sauces. Balanced flow vs control.

- Large (18 mm and up) — High-viscosity products with particulates (chunky sauces, smoothies with pulp, baby food with pieces). Large diameters reduce clogging and user frustration.

Rule of thumb: match maximum particle size to at least 1.5× spout opening and test worst-case temperature/age-related viscosity.

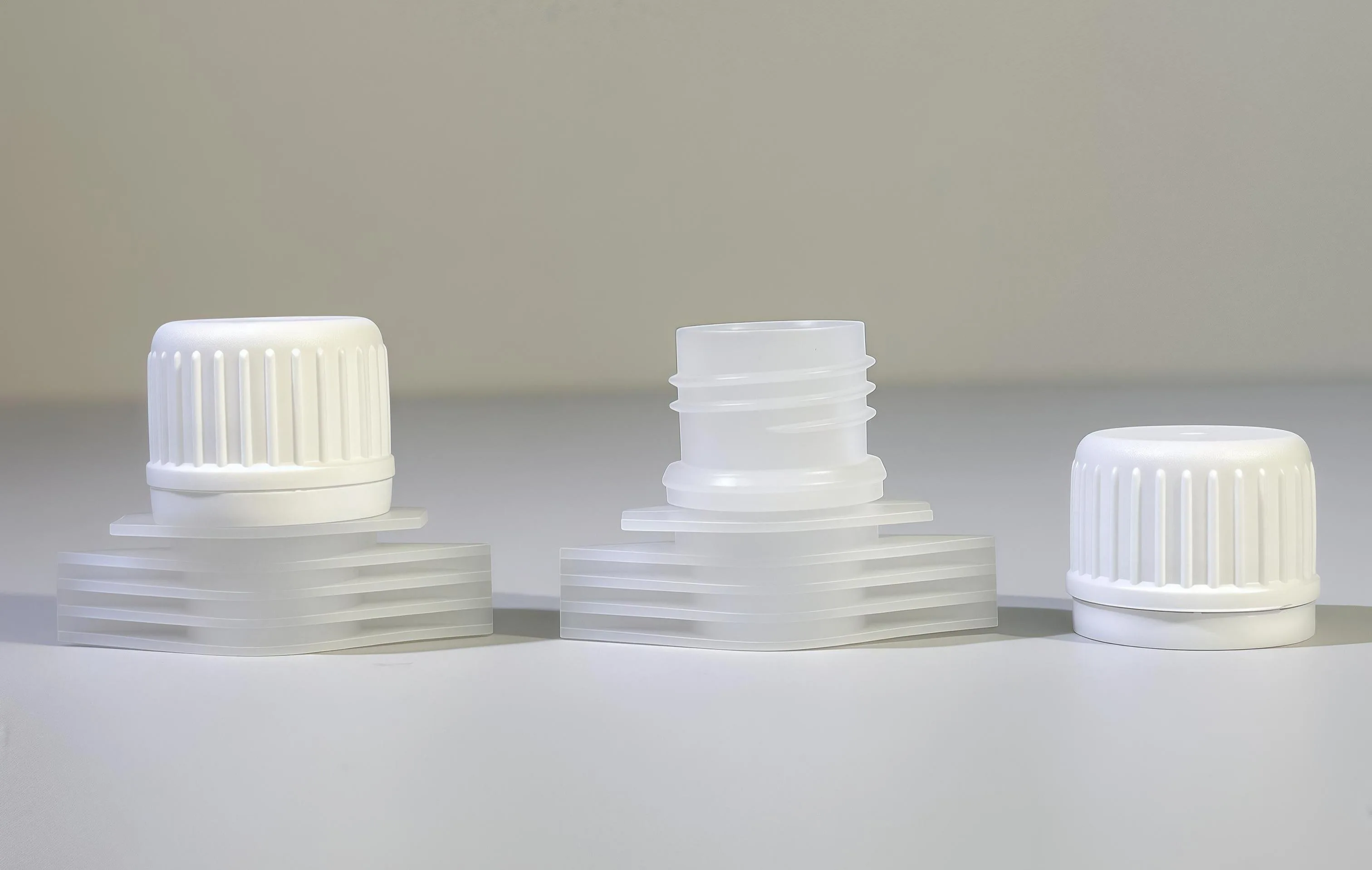

Spout Material & Cap Choices

Material selection affects heat resistance, sealing, and food safety:

- PE (Polyethylene)

- Flexible, good sealability, and cost-effective.

- Suitable for most ambient and chilled foods.

- PP (Polypropylene)

- Higher heat resistance — choose for hot-fill, retort, or applications requiring sterilization.

- Slightly stiffer; better torque retention on caps.

- Specialty materials/features

- Child-resistant designs, tamper-evident caps, dose-metering inserts, or anti-drip valves.

- Consider coated or compatibilized spout bodies when bonding to exotic laminates.

Always require food-contact grade resins and supplier Declarations of Compliance (DoC).

Application Matrix (Quick Reference)

| Product Type | Recommended spout type | Diameter | 素材 |

|---|---|---|---|

| Fruit juice / RTD beverage | Top spout (center) | 6–10 mm | PE |

| Protein shake/smoothie | Top spout or wide top | 10–16 mm | PP or PE |

| Baby puree/nutrition gel | Side spout (corner) | 12–16 mm | PP (for heat processes) |

| Honey/syrup | Side spout (reinforced corner) | 10–18 mm | PE |

| Ketchup / thick sauce | Side spout (wide) | 16–22 mm | PP |

Use this matrix as a starting point; always validate via pilot fills.

Filling Line & Production Compatibility

Spout selection must align with your filling and capping equipment:

- Filling speed vs spout geometry: Narrow spouts require slower fill times for viscous fluids; top spouts typically allow higher throughput.

- Capping torque and retention: This ensures the spout/cap interface tolerances match your capping heads to prevent leaks or cap failures.

- Spout welding: Some spouts require special forming collars or spout-applicator stations — factor in tooling lead times and changeover complexity.

- Pressure/leak testing: Implement routine burst/pressure checks and vacuum/leak tests for each production run.

Talk to your machinery vendors early; retrofitting spout applicators mid-project is costly.

Food Safety, Certifications & Migration Concerns

- Use FDA/EU-compliant materials and request CoC/CoA from spout suppliers.

- For hot-fill or retort items, validate spout material compatibility to withstand thermal cycles. PP is typically preferred for high-temperature processing.

- If using PCR content, ensure food-contact compatibility and confirm regulatory acceptance in target markets.

- Plan migration and organoleptic testing where spout materials contact the product directly for extended storage.

Common Mistakes and How to Avoid Them

- Choosing the spout by cost alone. Cheap spouts can cause leaks, recalls, or rework.

Fix: Evaluate total cost of ownership (leak rates, downtime, warranty cost). - Ignoring viscosity and particle size. Results in clogging and returns.

Fix: Lab test at worst-case temperatures and ages. - Not validating with your filler. Leads to production delays.

Fix: Run pilot trials on the actual line or a validated equivalent. - Overlooking user ergonomics. Poor dispensing frustrates consumers.

Fix: Field-test prototypes with representative users (athletes, parents, elderly).

Decision Flow: A Compact Checklist for Spec Sheets

- Define product viscosity range and particle sizes.

- Choose preferred user experience (squeeze vs pour).

- Select candidate spout type (side vs top) and diameter.

- Specify material (PE/PP) and cap features (tamper/tamper-evidence).

- Confirm compatibility with filling/capping equipment.

- Run lab and production pilots; perform leak and torque tests.

- Validate food safety (CoA/DoC), migration, and shelf-life.

結論

The optimal spout type is the intersection of product rheology, user needs, filling line capability, and regulatory constraints. For B2B buyers, the smartest approach is collaborative: involve your packaging engineer, filler OEM, and spout supplier from the very beginning of the スパウトパウチ design.

GQ PACKについて,GQ PACKはプロの軟包装メーカーとして、独立した設計チームと自動化された生産ラインを持っており、水ボトルラベル、シュリンクスリーブラベル、軟包装袋などの種類をカバーし、高性能のカスタマイズされた軟包装製品を提供し続けています,GQ PACK軟包装メーカーについて,GQ PACKは2008年に中国広東省で設立されました。我々は豊富な経験と特許技術を持つ軟包装メーカーです。製品は、カスタム水ボトルラベル、シュリンクスリーブラベル、スパウトポーチ、スタンドアップポーチなどが含まれ、飲料、食品、日用品、ペット用品業界で広く使用されています。先進的な高速印刷機とラミネート機を装備した16の生産ラインを持ち、経験豊富な技術チームにサポートされており、高品質でカスタマイズされたパッケージングソリューションを提供しています。,コアバリュー,品質,革新,持続可能性,効率性,企業ビジョン,グローバルな顧客のための信頼されるフレキシブルなパッケージングパートナーになる,顧客コミットメント,効率的な、専門的かつ高性能なパッケージングソリューションを提供する,高速10色グラビア印刷ワークショップ,私たちの高速10色グラビア印刷ワークショップは、高度な印刷設備を装備し、高精度自動印刷システムを採用し、極端な細部と豊かな色の完璧なプレゼンテーションを達成することができます。GQ-PACKの無溶剤ラミネーション工場では、有害な溶剤を使用しない無溶剤ラミネーションプロセスを採用しています、PACKの無溶剤ラミネートワークショップは、熱と圧力を利用して複数のフィルム層を接着する高度なラミネート技術を備えており、耐久性、強度、柔軟性に優れたパッケージを作成することができます。PACKはプロフェッショナルなUV硬化システムと熱硬化システムを備えており、硬化したフレキシブルパッケージングが優れた耐摩耗性と防水性を持つことを保証します。検査ワークショップ,私たちは最新の自動検査システムを使用し、包装されたすべての製品がお客様に届く前に最高の品質基準を満たしていることを確認しています。さらに、包装の耐久性、シールの完全性、バリア性を確認するために、包装のすべてのバッチで極端なテストを実行します。 高速スリッター工場,私たちの高速スリッター工場は、迅速かつきれいにフレキシブルフィルム、ラミネート、特殊フィルムを含むさまざまな材料を処理し、均一なロールサイズを提供し、卓越した速度と精度で大量生産の需要を満たす、軟包装製袋工場,当社の軟包装製袋工場は、品質、スピード、精度を重視し、専門的な裁断、製袋、シール設備を備えており、各バッチの製品が正確な寸法、確実なシール、きちんとした外観を持つことを保証します、+ M²,工場面積,生産ライン,技術スタッフ,百万人,年間生産量,GQ Packはフレキシブル包装ソリューションを提供します:,飲料,食品,日用品,パーソナルケア,ペット用品,特殊カートン,農業,技術的なアプリケーション,なぜ私たちを選ぶ,私たちの工場の表示,国際認証,GQ Packは、ISO 9001、FDA、LFGB、CE、RoHS認証などを含むフレキシブル包装の分野で多くの認証を得ています。私たちは、製品の品質とユーザーエクスペリエンスを重視し、常に生産プロセスにおける持続可能な開発を堅持しています。,私たちのビジョン,包装はカラフルで、創造的で、強力です。,私たちは、各フレキシブルパッケージを作るとき、我々は製品だけでなく、無限の可能性を見ています。,私たちは能力を持っており、我々は常にこのようなものです。,私たちが作成するフレキシブルパッケージは単なる容器ではありません、それはブランドの物語のキャリアであり、製品の品質の送信機です。,どのような産業であっても、私たちのパッケージは、製品が市場とシームレスに接続し、信頼と価値を伝えることができます。

Since GQ PACK was founded in 2008, we have dedicated ourselves to flexible food packaging. Now GQ PACK is regarded as a leading custom flexible food packaging manufacturer by the industry and our global clients.

We are wholesaling spout pouches now, one of our flagship products, and offering custom spout pouch solutions to meet your product requirements. In our custom flexible food packaging solution, GQ PACK delivered:

✅Practical tips from our expert teams

✅High-speed production with our 16 production lines

✅Strict quality control in ISO9001

✅International certified products, SGS, FDA, and TUV, etc.